Overview - Inventory

OVERVIEW - Inventory Module

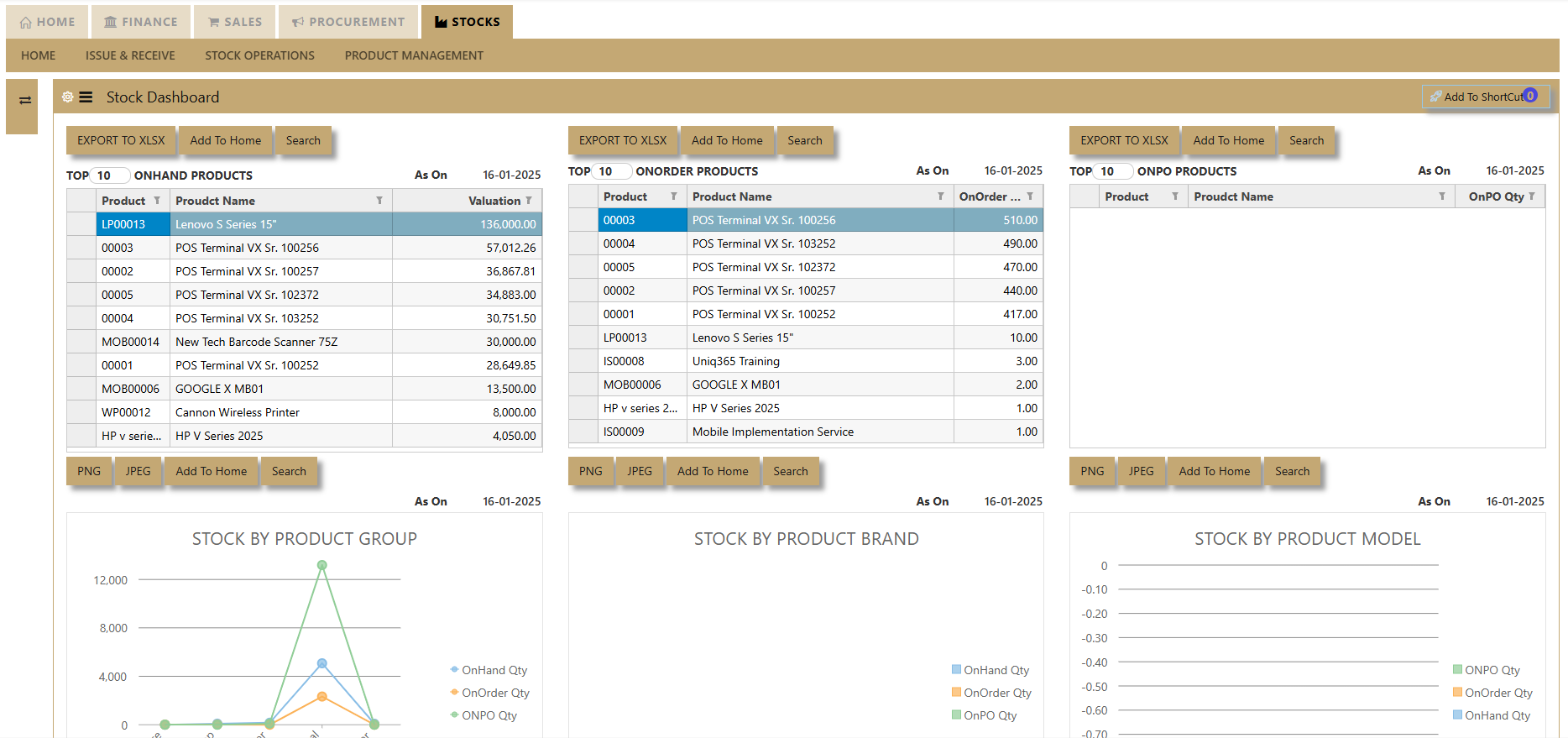

STOCKS MODULE

The Inventory module maintains the stock status and allows the user to enter the various stock transactions which updates the GL posting for stocks and cost of sales.

The Inventory Module in UNIQ365 allows the costing methods to be done in the following ways:

-

FIFO - First In First Out

-

Weighted Avg - Weighted Average

-

LIFO - Last In First Out

-

Standard Cost - Standard Costing

These choices are set in the Product Costing field at the Maintenance tab for Product & Service Maintenance.

Important: The most commonly used costing methods are FIFO and Weighted Average. If you need to allow for negative stocks, do not use FIFO. This costing method does not permit negative stocks. You may choose to use Weighted Average instead. It is advisable to use only one costing method for all the products in order to have a smooth and accurate cost recalculation process.

MENU NAVIGATION

The INVENTORY Module has 4 tabs, which are Home, Issue & Receive, Stock Operations, and Product Management.

Home where all the items in other three tabs will be listed down.

Issues & Receive is where transactions such as Stock Transactions, GRN Direct (SN), GRN ON order (SG), Sales Return (CC) as well as Purchase Return (SC) Stock Transfer are entered. It includes all the Reports and queries related to the Issues& receive transactions.

Operations is where transactions such as Stock Take, Opening Stocks, Stock transfer Direct, and Assembly items such as Stock Kit Assembly, Stock kit Disassembly and Bill of Materials are entered. It includes the Recalculate function, Barcode printing, Multiple Barcode Import and all the Reports and queries related to the Stock operation transactions.

Product Management is where master records for product are created.